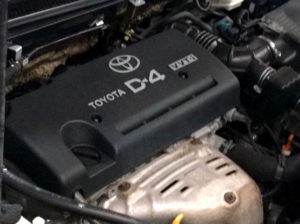

The Toyota 2AZ-FSE features a lightweight aluminum block with thin cast-iron cylinder liners and 16-valve DOHC aluminum head with four valves per cylinder (two intakes and two exhaust). The 2AZ-FSE engine is equipped with VVT-i (Variable Valve Timing with intelligence) on the intake camshaft, Toyota’s D-4 direct injection system, DIS (Direct Ignition System) with one ignition coil for each spark plug.

Cylinder bore and piston stroke are 88.5 mm (3.48 in) and 96.0 mm (3.78 in), respectively. Compression ratio rating is 11.0:1.

The engine produces 163 PS (120 kW; 161 HP) at 5,800 rpm of maximum horsepower and 231 Nm (23.6 kg·m; 170.5 ft·lb) at 3,800 rpm of peak torque.

The breakdown of the engine code is as follows:

- 2 – 2-nd generation engine

- AZ – Engine family

- F – Economy narrow-angle DOHC

- S – Gasoline direct injection system (D-4)

- E – Multi Point Fuel Injection

General information

| Engine Specifications | |

| Engine code | 2AZ-FSE |

| Layout | Four stroke, Inline-4 (Straight-4) |

| Fuel type | Gasoline (petrol) |

| Production | – |

| Displacement | 2.4 L, 2,362 cm2 (144.14 cu-in) |

| Fuel system | D-4 direct injection system |

| Power adder | None |

| Power output | 163 PS (120 kW; 161 HP) at 5,800 rpm |

| Torque output | 231 Nm (23.6 kg·m; 170.5 ft·lb) at 3,800 rpm |

| Firing order | 1-3-4-2 |

| Dimensions (L x W x H): | – |

| Weight | – |

Cylinder block

The 2AZ-FSE has an open-deck lightweight aluminum alloy cylinder block with cast-iron liners and a die-cast aluminum crankcase. The liner is thin so that boring is not possible. The forged steel crankshaft has eight counterweights and supported by five main bearings. The crankshaft is made of forged steel and balance shaft drive gear is installed onto the crankshaft. The Toyota 2AZ-FSE is equipped with two balance shafts.

The piston is made of aluminum alloy and skirt area is made compact and lightweight. The connecting rods and caps are made of high strength steel for weight reduction. Nutless-type plastic region tightening bolts of the connecting rod are used. The engine used pistons with two compression and single oil ring. The cylinder bore is 88.5 mm (3.48 in and the piston stroke is 96.0 mm (3.78 in). Compression ratio rating is 11.0:1.

| Cylinder block | ||

| Cylinder block alloy | Aluminium | |

| Compression ratio: | 11.0:1 | |

| Cylinder bore: | 88.5 mm (3.48 in) | |

| Piston stroke: | 96.0 mm (3.78 in) | |

| Number of piston rings (compression / oil): | 2 / 1 | |

| Number of main bearings: | 5 | |

| Cylinder inner diameter (standard): | 88.500-88.513 mm (3.4842-3.3848 in) | |

| Piston skirt diameter (standard): | 88.439-88.449 mm (3.4818-3.4822 in) | |

| Piston pin outer diameter: | 21.997-22.009 mm (0.8660-0.8665 in) | |

| Piston ring side clearance: | Top | 0.030-0.080 mm (0.0012-0.0031 in) |

| Second | 0.020-0.060 mm (0.0008-0.0024 in) | |

| Oil | 0.020-0.070 mm (0.0008-0.0028 in.) | |

| Piston ring end gap: | Top | 0.22-0.32 mm (0.0087-0.0126 in.) |

| Second | 0.50-0.60 mm (0.0197-0.0236 in.) | |

| Oil | 0.10-0.35 mm (0.0039-0.0138 in.) | |

| Crankshaft main journal diameter: | 54.998-55.000 mm (2.1652-2.1653 in) | |

| Crankpin diameter: | 47.990-48.000 mm (1.8894-1.8898 in) | |

Main bearing cap bolts tightening procedure and torque specs:

- Step 1: 20 Nm; 2.0 kg·m; 15 ft·lb

- Step 2: 40 Nm; 4.0 kg·m; 29 ft·lb

After securing bearing cap bolts, make sure crankshaft turns smoothly by hand.

Connecting rod bearing bolts

- Step 1: 25 Nm; 2.5 kg·m; 18 ft·lb

- Step 2: Turn bolts 90°

Cylinder head

The cylinder head is made of strong, light aluminum alloy which gives it good cooling efficiency. Each camshaft is supported by five bearings. The dual overhead camshafts are driven by a roller chain. The timing chain is lubricated by an oil jet. Each cylinder is equipped with 2 intake valves and 2 exhaust valves. Valve diameters are 34.0 mm (1.3 in) for intake and 29.5 mm (1.2 in) for exhaust.

The engine is equipped with lightweight magnesium alloy diecast cylinder head cover. The cylinder head cover gasket and the spark plug gasket is integrated to reduce the number of parts. A steel-laminate type cylinder head gasket is used.

| Cylinder head | ||

| Valve Arrangement: | DOHC, chain drive | |

| Valves: | 16 (4 valves per cylinder) | |

| Valve head diameter: | INTAKE | 34.0 mm (1.3385 in) |

| EXHAUST | 29.5 mm (1.1614 in) | |

| Valve length: | INTAKE | 101.71 mm (4.004 in) |

| EXHAUST | 101.21 mm (3.984 in) | |

| Valve stem diameter: | INTAKE | 5.470-5.485 mm (0.2153-0.2159 in) |

| EXHAUST | 5.465-5.480 mm (0.151 – 0.2157 in) | |

| Valve spring free length: | 45.7 mm (1.7990 in) | |

| Outer camshaft journal diameter: | №1 | 35.971-35.985 mm (1.4162-1.4167 in) |

| №2, 3, 4, 5 | 22.959-22.975 mm (0.9039-0.9045 in) | |

Head tightening procedure and torque specs:

- Step 1: 79 Nm; 8.0 kg·m; 58 ft·lb

- Step 2: Turn all bolts 90°

Camshaft bearing cap bolts

- № 1:30 Nm; 3.0 kg·m; 22 ft·lb

- Other:9 Nm; 0.9 kg·m; 6.4 ft·lb

Maintenance data

| Compression pressure | |

| Standard | 13.0 kg/m2 / 200 rpm |

| Minimun | 11.0 kg/m2 / 200 rpm |

| Compression differential limit between cylinders | 1.0 kg/m2 / 200 rpm |

| Oil system | |

| Oil consumption , L/1000 km (qt. per miles) | up to 0.5 (1 qt. per 1200 miles) |

| Recommended engine oil | 5W-20, 5W-30, 10W-30 |

| Oil type API | SJ |

| Engine oil capacity (Refill capacity) |

With filter change: 3.8 liters (4.0 US qts, 3.3 Imp. qts) Without filter change: 3.6 liters (3.8 US qts, 3.2 Imp. qts) |

| Oil change interval, km (miles) | 10,000 (6,000) |

| Oil Pressure, kPa (bar, kg/cm 2, psi) |

Idle speed: More than 60 (0.6, 0.61, 9) 2,000 rpm: More than 270 (2.7, 2.8, 39) |

| Ignition system | |

| Spark plug | DENSO: SK20R11 NGK: IFR6A11 |

| Spark plug gap | 1.1 mm (0.043 in) |

Vehicle applications

| Model | Years Produced |

| Toyota Avensis | – |

1